Ti 2 Coil Tubing Price

Titanium Composition

| Grade | Description |

| Titanium Grade 1 | Unalloyed titanium, low oxygen, low strength |

| Titanium Grade 2 | Unalloyed titanium, standard oxygen, medium strength |

| Titanium Grade 3 | Unalloyed titanium, medium oxygen, high strength |

| Titanium Grade 4 | Unalloyed titanium, high oxygen, extra high strength |

| Titanium Grade 5 | Titanium alloy (6% aluminum, 4% vanadium) |

| Titanium Grade 7 | Unalloyed titanium plus 0.12% to 0.25% palladium, standard oxygen, medium strength |

| Titanium Grade 9 | Titanium alloy (3% aluminum, 2.5% vanadium), high strength. Mainly aerospace applications |

| Titanium Grade 11 | Unalloyed titanium plus 0.12% to 0.25% palladium, low oxygen, low strength |

| Titanium Grade 12 | Titanium alloy (0.3% molybdenum, 0.8% nickel), high strength |

| Titanium Grade 13 | Titanium alloy (0.5% nickel, 0.05% ruthenium), low oxygen |

| Titanium Grade 14 | Titanium alloy (0.5% nickel, 0.05% ruthenium), standard oxygen |

| Titanium Grade 15 | Titanium alloy (0.5% nickel, 0.05% ruthenium), medium oxygen |

| Titanium Grade 16 | Unalloyed titanium plus 0.04% to 0.08% palladium, standard oxygen, medium strength |

| Titanium Grade 17 | Unalloyed titanium plus 0.04% to 0.08% palladium, low oxygen, low strength |

| Titanium Grade 18 | Titanium alloy (3% aluminum, 2.5% vanadium plus 0.04% to 0.08% palladium), |

| Titanium Grade 19 | Titanium alloy (3% aluminum, 8% vanadium, 6% chromium, 4% zirconium, 4% molybdenum) |

| Titanium Grade 20 | Titanium alloy (3% aluminum, 8% vanadium, 6% chromium, 4% zirconium, 4% molybdenum) plus 0.04% to 0.08% palladium |

| Titanium Grade 21 | Titanium alloy (15% molybdenum, 3% aluminum, 2.7% niobium, 0.25% silicon) |

| Titanium Grade 23 | Titanium alloy (6% aluminum, 4% vanadium, extra low interstitial, ELI) |

| Titanium Grade 24 | Titanium alloy (6% aluminum, 4% vanadium) plus 0.04% to 0.08% palladium |

| Titanium Grade 25 | Titanium alloy (6% aluminum, 4% vanadium) plus 0.3% to 0.8% nickel and 0.04% to 0.08% palladium |

| Titanium Grade 26 | Unalloyed titanium plus 0.08% to 0.14% ruthenium, standard oxygen, medium strength |

| Titanium Grade 27 | Unalloyed titanium plus 0.08% to 0.14% ruthenium, low oxygen,low strength |

| Titanium Grade 28 | Titanium alloy (3% aluminum, 2.5% vanadium) plus 0.08% to 0.14% ruthenium |

| Titanium Grade 29 | Titanium alloy (6% aluminum, 4% vanadium with extra low interstitial elements (ELI) plus 0.08% to 0.14% ruthenium |

Titanium & Titanium Alloys MIL-T Specifications

| AMS-T-9046 (Issued 1999) | |

| Commercially Pure Titanium | |

| (CP) CODE | Yield Strength (min. ksi) |

| CP-1 | (70 KSI-YS) |

| CP-2 | (55 KSI-YS) |

| CP-3 | (40 KSI-YS) |

| CP-4 | (30 KSI-YS) |

| Alpha Titanium Alloys (A) | |

| CODE | Composition |

| A-1 | 5AL-2.5Sn |

| A-2 | 5AL-2.5Sn (ELI) |

| A-3 | 6AL-2Cb-1Ta-0.8Mo |

| A-4 | 8AL-1Mo-1V |

| Alpha-Beta Titanium Alloy | |

| (AB) CODE | Composition |

| AB-1 | 6AL-4V |

| AB-2 | 6AL-4V (ELI) |

| AB-3 | 6AL-6V-2Sn |

| AB-4 | 6AL-2Sn-4Zr-2Mo |

| AB-5 | 3.AL-2.5V |

| AB-6 | 8Mn |

| Beta Titanium Alloys (B) | |

| CODE | Composition |

| B-1 | 13V-11Cr-3AL |

| B-2 | 11.5Mo-6Zr-4.5Sn |

| B-3 | 3AL-8V-6Cr-4Mo-4Zr |

| B-4 | 8Mo-8V-2Fe-3AL |

ASTM B338

Size Range

| Outside Diameter (OD) | Wall Thickness |

| .125"–.500" | .035” |

Chemical Requirements

Titanium Grade 2 (UNS R50400)

Composition %

| N Nitrogen |

C Carbon |

H Hydrogen |

Fe Iron |

O Oxygen |

Residuals Each |

Residuals Total |

Ti Titanium |

| 0.03 max | 0.08 max | 0.015 max | 0.30 max | 0.25 max | 0.10max | 0.4 max | Balance |

Dimensional Tolerances

| OD | OD Tolerance | Wall Tolerance |

| .125"–.500" | +.003” | ± 10% |

Mechanical Properties

| Yield Strength: | 40 ksi min |

| Tensile Strength: | 50 ksi min |

| Elongation (min 2"): | 20% |

| Hardness (Rockwell B Scale) | 80 HRB max |

Other Designations

Other designations equivalent to grade 310S stainless steel are listed in the following table.

|

AMS 5521 |

ASTM A240 |

ASTM A479 |

DIN 1.4845 |

|

AMS 5572 |

ASTM A249 |

ASTM A511 |

QQ S763 |

|

AMS 5577 |

ASTM A276 |

ASTM A554 |

ASME SA240 |

|

AMS 5651 |

ASTM A312 |

ASTM A580 |

ASME SA479 |

|

ASTM A167 |

ASTM A314 |

ASTM A813 |

SAE 30310S |

|

ASTM A213 |

ASTM A473 |

ASTM A814 |

SAE J405 (30310S) |

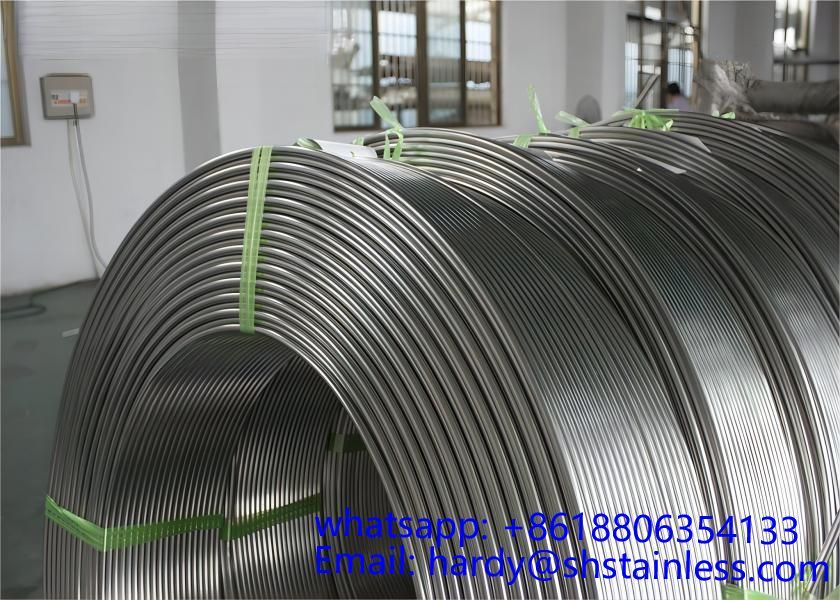

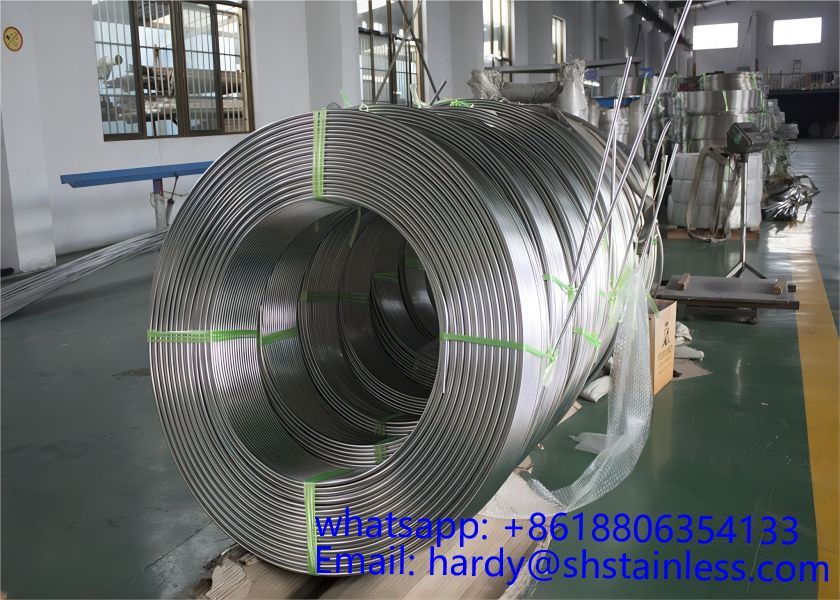

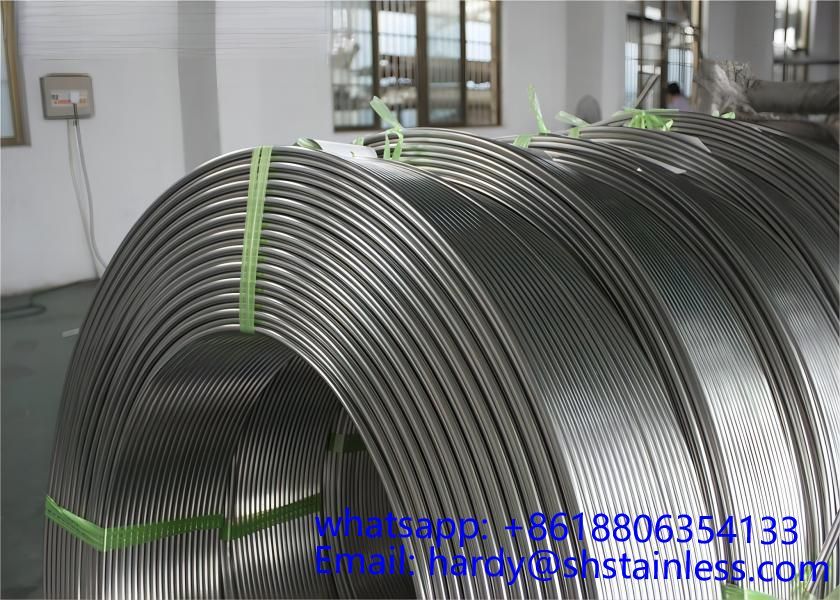

Alloy 310s stainless steel coiled tube

Liaochengsihe stainless steel material Limited company is a professional manufacturer direct marketing of stainless steel coiled tube stainless steel pipe ,stainless steel condenser stainless steel precision pipe.has two production lines can produce continuous oil pipe, equipment is perfect

Factoy Photos

Inspection

Shipping & Packing

Test Report