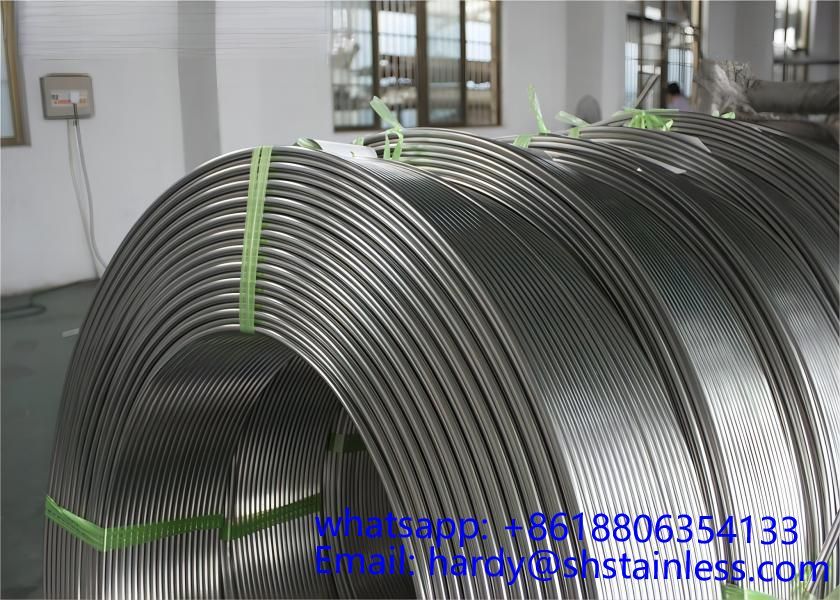

321 stainless steel 8*1 mm coiled tube

Alloy 347H is a stabilized, austenitic, chromium steel containing columbium which allows for the elimination of carbide precipitation, and, consequently, intergranualr corrosion. Alloy 347 is stabilized by the additions of chromium and tantalum and offers higher creep and stress rupture properties than alloy 304 and 304L which may also be used for exposures where sensitization and intergranualr corrosion are of concern. The addition of columbium also allows Alloy 347 to have excellent corrosion resistance, even superior to that of alloy 321. 347H is the higher carbon composition form of Alloy 347 and demonstrates improved high temperature and creep properties. Haosteel Stainless inventory now includes Alloy 347/347H (UNS S34700/S34709) in sheet, sheet coil, plate, round bar, processed flat bar and tubular products.

347H stainless steel coiled tube

Chemical composition:

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Nb |

|

0.04-0.1 |

≤ 0.75 |

≤ 2.0 |

≤ 0.045 |

≤ 0.03 |

17.0 - 19.0 |

9.0 - 13.0 |

8C - 1.0 |

347H stainless steel coiled tube

Physical Properties:

347H stainless steel coiled tube

Annealed:

Ultimate Tensile Strength – 75KSI min (515 MPA min)

Yield Strength (0.2% Offset) –30 KSI min (205 MPA min)

Elongation – 40% min

Hardness – HRB92max (201HV max)