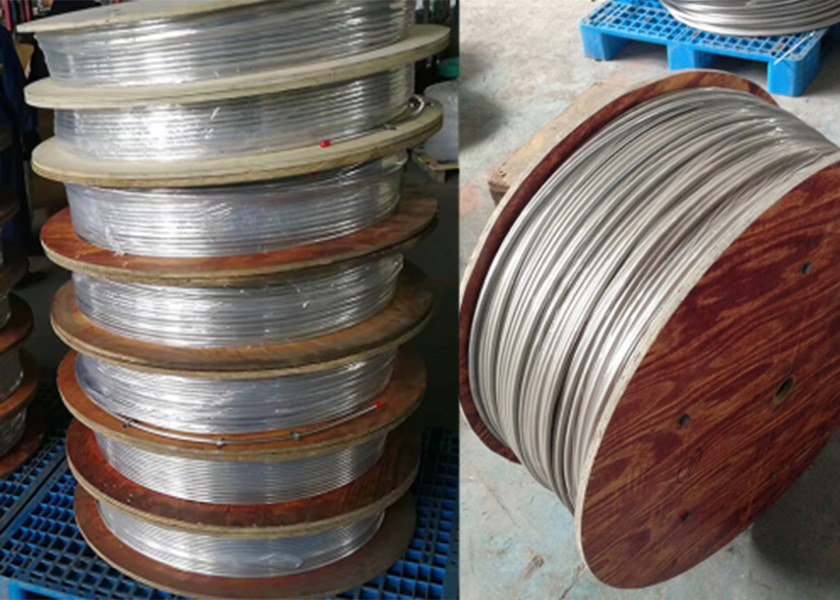

Super Alloy INCOLOY Alloy 800 (UNS N08800) 9.52*0.89 mm coiled tubing

Introduction

Super Alloy INCOLOY Alloy 800 (UNS N08800) 9.52*0.89 mm coiled tubing

INCOLOY alloys belong to the category of super austenitic stainless steels. These alloys have nickel-chromium-iron as the base metals, with additives such as molybdenum, copper, nitrogen and silicon. These alloys are known for their excellent strength at elevated temperatures and good corrosion resistance in a variety of corrosive environments.

INCOLOY alloy 800 is an alloy of nickel, iron and chromium. The alloy is capable of remaining stable and maintaining its austenitic structure even after long time exposures to high temperatures. Other characteristics of the alloy are good strength, and high resistance to oxidizing, reducing and aqueous environments. The standard forms in which this alloy is available are round, flats, forging stock, tube, plate, sheet, wire and strip.

This datasheet will look into the chemical composition, properties and applications of INCOLOY 800.

Chemical Composition

Super Alloy INCOLOY Alloy 800 (UNS N08800) 9.52*0.89 mm coiled tubing

The chemical composition of INCOLOY alloy 800 is given in the following table.

| Element | Content (%) |

|---|---|

| Iron, Fe | ≥39.5 |

| Nickel, Ni | 30-35 |

| Chromium, Cr | 19-23 |

| Manganese, Mn | ≤1.5 |

| Others | Remainder |

Physical Properties

Super Alloy INCOLOY Alloy 800 (UNS N08800) 9.52*0.89 mm coiled tubing

The following table discusses the physical properties of INCOLOY alloy 800.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 7.94 gm/cm3 | 0.287 lb/in3 |

Mechanical Properties

Super Alloy INCOLOY Alloy 800 (UNS N08800) 9.52*0.89 mm coiled tubing

The mechanical properties of INCOLOY alloy 800 are tabulated below.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength(annealed) | 600 MPa | 87 ksi |

| Yield strength(annealed) | 275 MPa | 39.9 ksi |

| Elongation at Break | 45% | 45% |

Other Designations

Some of the designations used to denote INCOLOY alloy 800 are listed below:

| UNS N08800 | AMS 5766 | AMS 5871 | ASTM B163 | ASTM B366 |

| ASTM B407 | ASTM B408 | ASTM B409 | ASTM B514 | ASTM B515 |

| ASTM B564 | DIN 1.4876 |

Fabrication

Machinability

Related Stories

- UTC Aerospace Systems to Supply Wheels and Carbon Brakes for Aeroflot’s 737-800 Aircraft

- Nickel Alloys and Iron Nickel Alloys

- Polyamide 6/6 – Nylon 6/6 – PA 6/6 Super-Tough

Machining characteristics of this INCOLOY alloy 800 are similar to that of iron-based alloys. This alloy tends to work-harden during machining.

Welding

INCOLOY alloy 800 can be welded by common welding techniques, using a matching filler metal.

Forming

This alloy exhibits good ductility and hence can be formed using conventional methods.

Hot working

INCOLOY alloy 800 can be hot worked at temperature ranges of 871-1232°C (1600-2250°F).

Cold Working

Cold working may be done on the alloy using standard tooling.

Annealing

INCOLOY alloy 800 may be annealed after cold working. Annealing should be done at 982°C (1800°F) for 15 min and then the alloy should be air cooled.

Applications

INCOLOY alloy 800 is used in the following applications:

- Heat exchangers

- Carburising equipment

- Heating elements

- Sheathing and nuclear steam generator tubing.