Conductivity changes in cooling water indicate process breakthrough

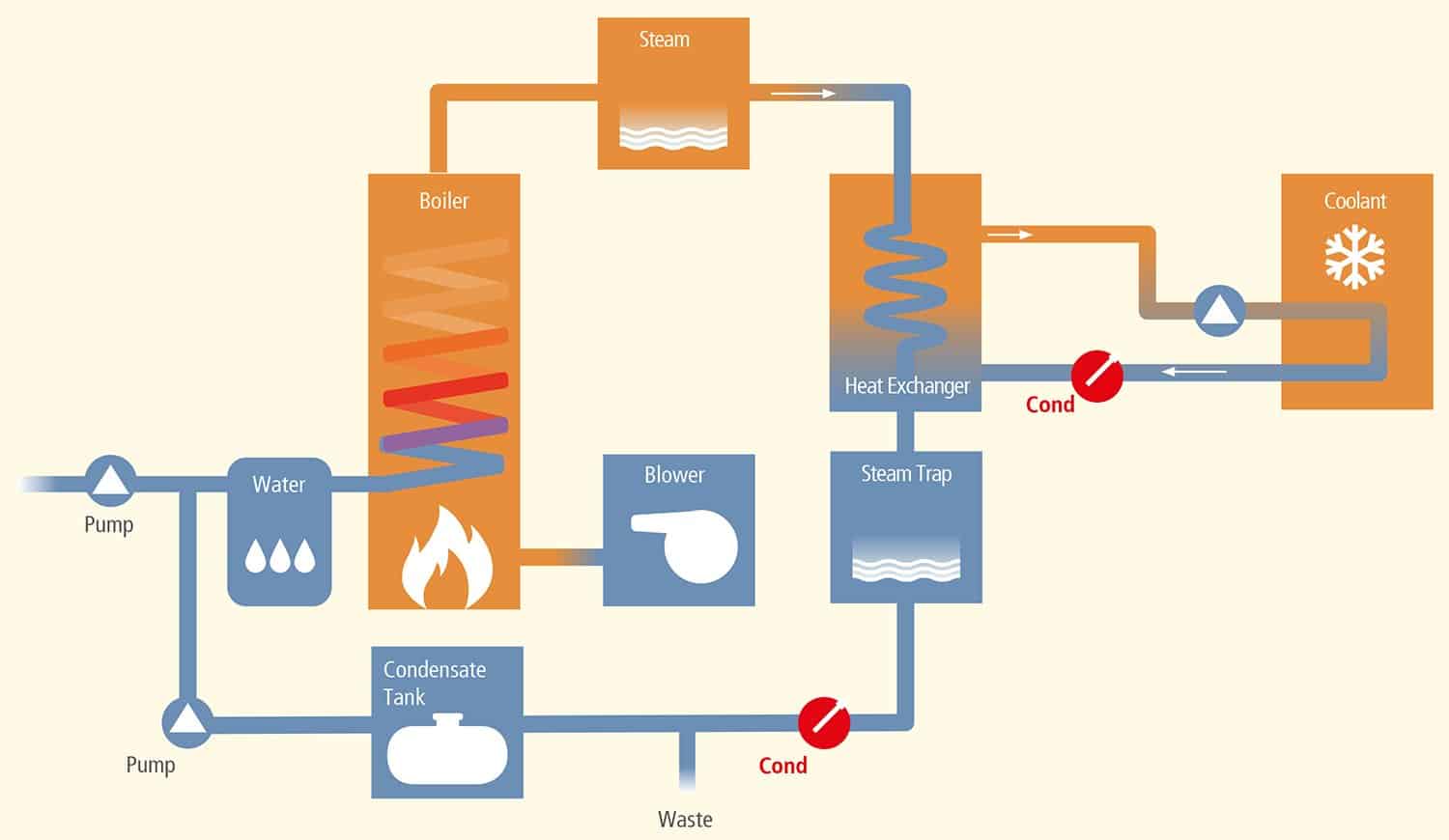

Cooled steam precipitates as condensate with a high level of purity and therefore low conductivity. Since increased conductivity is an indication of contamination, measuring the conductivity of condensate is a reliable method for verifying that plants are functioning properly and monitoring for process breakthrough.

As a rule, the measuring points used to accomplish this consist of different conductivity sensors connected to several analyzers/transmitters in a control cabinet. But this requires extensive cabling and takes up lots of space in the cabinet.

Memosens digital sensor technology offers a compact, no-maintenance solution: with the SE615 Memosens conductivity sensor, condensate contamination can be determined within the broad 10 µS/cm – 20 mS range. The very thin sensor with a PG 13.5

connection thread can be simply adapted to the process in-line using a matching static holder (ARI106, for example) downstream from the heat exchanger at a point where the temperature is no longer high. For higher pressure and temperature requirements, we recommend two other sensors: the SE604 (for low 0.001 – 1000 µS/cm measuring ranges) or SE630 (for higher measuring ranges of up to 50 mS/cm) with direct process adaptation via G 1″ or NPT thread.

All sensors have an integrated temperature detector for correct temperature compensation. When connecting the measuring points to the control system, the compact (12 mm wide) DIN rail mounted MemoRail transmitters reduce the amounts of space and cable required in the control cabinet. And two standard-signal current outputs ensure floating transmission of measured process values and temperature to the PLC.

Post time: Dec-27-2022