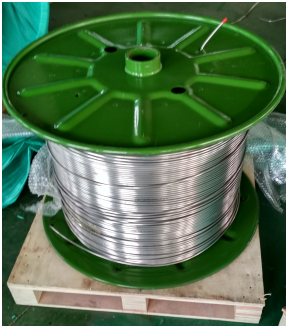

316/316L stainless steel 9.52*1.69 mm coiled tube

Stainless Steel 316 Coil Tube Chemical Composition

Accordin to the Stainless Steel 316 Coil Tube Manufacturer, the chemical composition of stainless steel 316 coil tube is as follows: Carbon – 0.08%, Manganese – 2.00%, Phosphorus – 0.045%, Sulfur – 0.030%. Its other elements include Chromium (16-18%), Nickel (10-14%), Molybdenum (2-3%), and Nitrogen (-0.1%).

316/316L stainless steel 9.52*1.69 mm coiled tube

|

Grade |

Chromium |

Nickel |

Carbon |

Magnesium |

Molybdenum |

Silicon |

Phosphorus |

sulfur |

|

316 |

16 – 18 |

10 – 14 |

0.03 |

2 |

2 – 3 |

1 |

0.045 |

0.030 |

Stainless Steel 316 Coil Tube Mechanical Properties

Stainless Steel 316 coil tube is a type of stainless steel that has been alloyed with molybdenum and nickel in order to improve its resistance to corrosion and pitting. It has excellent mechanical properties, including high strength, toughness, and ductility making it the perfect choice of Stainless Steel 316 Coil Tube Manufacturer.

|

Material |

Temperature |

Tensile Strength |

Yield Strength |

Elongation |

|

316 |

1900 |

75 |

30 |

35 |

316/316L stainless steel 9.52*1.69 mm coiled tube

1. Process Method: Cold Drawn, Cold Rolled, Bright Annealed

2. Surface Finish: Bright Annealed

3. Standards: ASTM A213/ASME SA213, ASTM A269/ASME SA269, EN10216-5, JIS G3463, etc

4. Materials: TP304/L/H; TP316/L/Ti; TP309S; TP310S; TP321/H; TP317L; TP347/H, etc

5. Ends: Beveled End/Plain End

6. Size Range:

316/316L stainless steel 9.52*1.69 mm coiled tube

OD: (4.76mm-25.4mm),

WT: (0.71mm-2.11mm)

7. Package: woven bags

8. Tolerances: According to the specification or customer’s request and drawings

9. Applications: Instrument tubing, chemical injection tubing, hydraulic tubing, high pressure tubing, cleaned tubing, heat exchanger, etc

10. Inspection: PMI Test, Hydraulic Test, Eddy Current Test, Non-destructive Test, etc

11. Advantages:

Equipments:

a. More than 70 meters long Cold drawing machine

b. The temperature of Bright annealed furnace can reach 1350℃

c. Ultrasonic & Eddy Current Testing United Equipment

Coil tube:

a. Reduce your cost

b. Improve the security

c. Compact package for shipment and storage