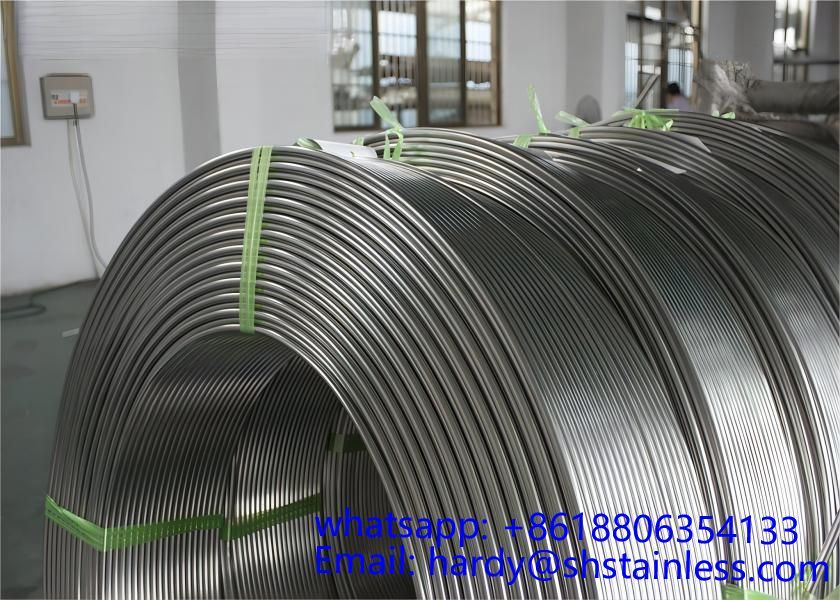

254SMO stainless steel 9.53*1.24 coiled tube

National standards: UNS S31254, DIN/EN 1.4547, ASTM A280, ASME SA-280

Supporting welding materials: ErNICRMO-3 wire, EnICRmo-3 electrode

Chemical composition:

254SMO stainless steel 9.53*1.24 coiled tube

| Grade | % | Ni | Cr | Mo | Cu | N | C | Mn | Si | P | S |

| 254SMO | MIN | 17.5 | 19.5 | 6 | 0.5 | 0.18 | |||||

| MAX | 18.5 | 20.5 | 6.5 | 1 | 0.22 | 0.02 | 1 | 0.8 | 0.03 | 0.01 |

High temperature resistant

254SMO stainless steel 9.53*1.24 coiled tube

1. Extensive field experiments and extensive experience have shown that even at slightly higher temperatures, 254SMO has a very high resistance to crevice-corrosion in seawater, which only a few types of stainless steel have.

2. 254SMO’s corrosion resistance in acidic and oxidizing halide solutions such as those required for paper bleaching production is comparable to that of the most resistant nickel-base and titanium alloys.

3. Because of its high nitrogen content, 254SMO has a higher mechanical strength than other kinds of austenitic stainless steel. In addition, 254SMO has high ductility and impact strength as well as good weldability.

4. The high molybdenum content of 254SMO enables it to have a higher oxidation rate at annealing, resulting in a rougher surface than ordinary stainless steel after pickling. But this has no adverse effect on the corrosion resistance of the steel.

Application:

254SMO stainless steel 9.53*1.24 coiled tube

1. Ocean: Marine structures in the Marine environment, seawater desalination, mariculture, heat exchange of seawater, such as thin-walled condensing pipes cooled by seawater in power plants, desalination equipment, even in equipment where seawater may not flow, etc.

2. Environmental protection field: thermal power generation flue gas desulfurization device, waste water treatment, the main parts are: absorber tower body, flue, door panels, inner parts, spray system, etc.

3. Energy: atomic power generation, comprehensive utilization of coal, tidal power generation, etc.

4. Petrochemical industry: oil refining, chemical equipment, petrochemical equipment, such as bellows in petrochemical equipment, etc.

5. Food field: salt making, desalination industry, such as salt making or desalination equipment, soy sauce brewing, etc.

6. High concentration chloride ion environment: papermaking industry, pulp and paper bleaching equipment, such as pulp digesters, bleaching equipment, filter scrubber barrels and press rollers and other bleaching equipment