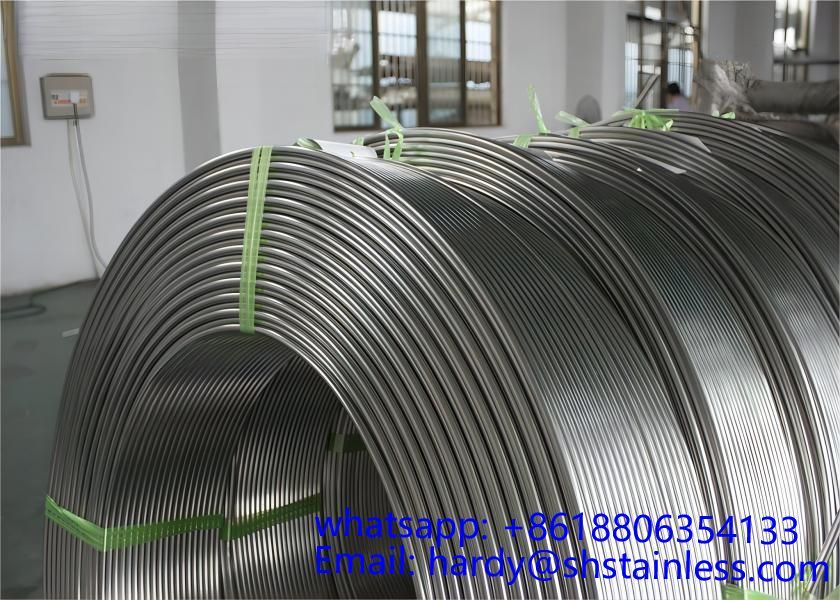

2507 stainless steel 10*1mm coiled capillary tubing

MATERIAL DESCRIPTION

2507 stainless steel 10*1mm coiled capillary tubing

All our super-duplex materials are produced by Norsok M-650 Ed.4 and/ or ISO 17782 qualified manufacturers.

Super Duplex UNS S32750 is the most common super duplex grade in the market. UNS S32750 is a duplex especially designed for service in aggressive chloride-containing environments. It has very good resistance to localized corrosion and stress corrosion cracking in combination with high mechanical strength. It is widely used in oil & gas, hydropower, pressure vessels, pulp & paper, structural components and chemical tankers.

Applications

2507 stainless steel 10*1mm coiled capillary tubing

The main applications are for details with special requirements for high corrosion resistance.

UNS S32750 is characterized by:

- High resistance to stress corrosion cracking in halide containing environments.

- High resistance to pitting and crevice corrosion.

- High resistance to general corrosion.

- High mechanical strength.

- High resistance to erosion corrosion and corrosion fatigue.

Heat Treatment2507 stainless steel 10*1mm coiled capillary tubing

Solution annealing in the range of 1100°C followed by water quenching.

Weldability

Very good.

Chemical Composition (Specific for Bars)

| Weight % | C | Mn | P | S | Si | Cr | Ni | Mo | Cu | N | PRE |

| Min. | 24,0 | 6,00 | 3,00 | 0,24 | 41 | ||||||

| Max. | 0,030 | 1,20 | 0,025 | 0,010 | 0,80 | 26,0 | 8,00 | 4,50 | 0,50 | 0,32 |

PREN = % Cr + 3.3 % Mo + 16 % N ≥ 41

Reference Standards

General:

- Norsok M-650 Ed.4 qualified manufacturers

- PED 2014/68/EU Annex I section 4.3

- AD2000 W0 (W2/W10)

- NACE MR0175/ ISO 15156-3 and NACE MR0103/ISO 17945

- 2507 stainless steel 10*1mm coiled capillary tubing

Plate, sheet and coil:

- ASTM A240, EN 10028-7, EN 10088-2, EN 10088-4, Norsok M-630 MDS D55

Bar and forging:

- ASTM A276, ASTM A479, ASTM A182, EN 10088-3, Norsok M-630 MDS D54/D57

Other products:

- As per applicable ASTM and/or EN standards and Norsok M-630 MDS

Mechanical Properties (Typical)

| Yield strength Rp0.2, MPa |

Tensile strength Rm, MPa |

Elongation [%] |

Hardness [HB] |

Impact, Charpy-V, -46ºC [J] |

|

| BAR | ≥ 550 | ≥ 750 | ≥ 25 | ≤ 300 | ≥ 65 |

| PLATE CR (COIL) | ≥ 550 | 750 – 1000 | ≥ 25 | ≤ 310 | ≥ 45 |

| PLATE HR (COIL) | ≥ 550 | 750 – 1000 | ≥ 25 | ≤ 310 | ≥ 45 |

| PLATE (QUARTO) | ≥ 550 | 750 – 930 | ≥ 25 | ≤ 310 | ≥ 45 |