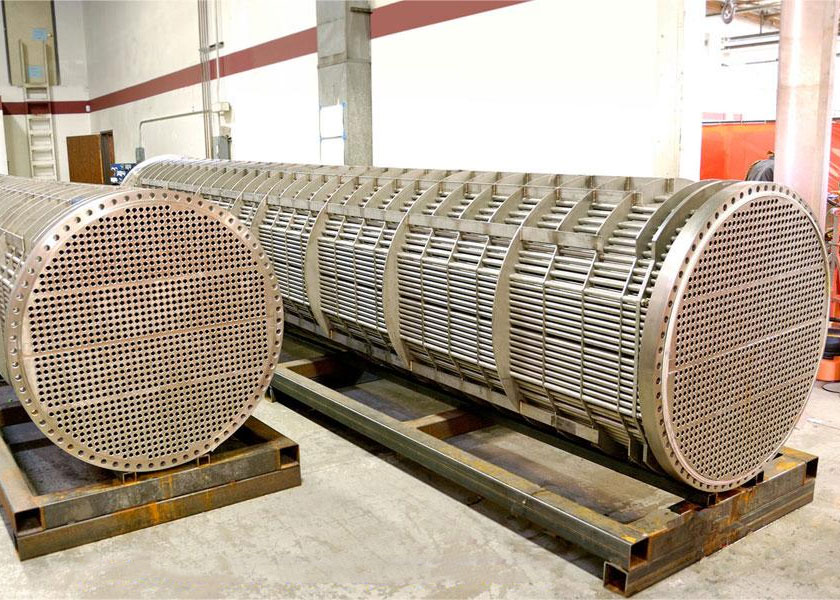

317, 317L stainless steel heat exchanger

Material description

- Material description

It is austenitic stainless steel with a higher amount of chromium, nickel and molybdenum element that offers excellent corrosion resistance ability. It has a higher resistance to chemical effects from different acids. The alloy 317L is a lower carbon content allows for resistance to intergranular corrosion. It has higher tensile strength at higher temperatures. It is weldable with all standard welding process and is readily machinable with standard machines. - Fabrication data

These are hot worked using all standard hot working process. It is heated in the temperatures between 1149 to 1260 degree C. The temperature should be maintained below 927 degree C. The post-work annealing process is induced on it to retain higher corrosion resistance attributes. Moreover, this process is performed to reduce internal stress. SS tubes are easily drawn with cold working operations. The heat treatment will not affect the structure, however, cold working operation is followed to get harden structures.

The solution annealing is performed in the temperatures between 1010- 1121 degree C and followed by cooling. It is subjected to an industrial finishing process to acquire precise dimensions and surface finish. - Quality management

Our entire team is recharged to uphold the commitment of quality. Our core strength is a committed and motivated team. We are dedicated to providing high-quality products and services to customers. As we are global suppliers, we calibrate our products with internationally approved standards to ensure the quality of the products. Hardness test, thermal conductivity test, leakage test, positive material test, intergranular corrosion test, and mechanical test, given tests, are performed by us in the initial stage.

The final inspection is performed by third-party authorities. Moreover, secondary tests are the destructive test, compression test, tensile test and many more.

Stainless Steel 317 / 317L Heat Exchanger Tubes are available in a variety of finishes, one can get from us.

Ss 317 / 317l Heat Exchanger Tubes Specification

- Range : 10 mm OD to 50.8 mm OD

- Outer Diameter : 9.52 mm O.D to 50.80 mm O.D

- Thickness : 0.70 mm to 12.70 mm

- Length : up to 12 Meters Leg Length & Customed Length

- Specifications : ASTM A249 / ASTM SA249

- Finish : Annealed, pickled & polished, BA

Equivalent Grade of Stainless Steel 317 / 317L Heat Exchanger Tubes

|

STANDARD |

UNS |

WERKSTOFF NR. |

|

SS 317 |

S31700 |

1.4449 |

|

SS 317L |

S31703 |

1.4438 |

Chemical Composition of SS 317 / 317L Heat Exchanger Tube

|

SS |

317 |

317L |

|

Ni |

11 – 14 |

11 – 15 |

|

Fe |

– |

– |

|

Cr |

18 – 20 |

18 – 20 |

|

C |

0.08 max |

0.35 max |

|

Si |

1 max |

1 max |

|

Mn |

2 max |

2 max |

|

P |

0.045 max |

0.040 max |

|

S |

0.030 max |

0.03 max |

|

Mo |

3.00 – 4.00 |

3 – 4 |

Mechanical Properties of SS 317 / 317L Heat Exchanger Tubes

|

Density |

8.0 g/cm3 |

|

Melting Point |

1454 °C (2650 °F) |

|

Tensile Strength |

Psi – 75000 , MPa – 515 |

|

Yield Strength (0.2%Offset) |

Psi – 30000 , MPa – 205 |

|

Elongation |

35 % |

Write your message here and send it to us